OEM/ODM China Wt2080 Led Power Driver Tester - C0041 – COFriction Tester – Drick

Short Description:

This extremely easy to use instrument has been manufactured to determinethe static and kinetic friction of plastic film, sheeting and paper and other sheeted material using the horizontal plane principle. The coefficient of friction (COF)is anumber which represents the frictionbetween two surfaces. Friction is aresisting force relating to molecularstructure of a surface of one materialas it slides over the surface of thesame or another material. Moleculesfrom one surface link with molecules f...

OEM/ODM China Wt2080 Led Power Driver Tester - C0041 – COFriction Tester – Drick Detail:

This extremely easy to use instrument has been manufactured to determinethe static

and kinetic friction of plastic film, sheeting and paper and other sheeted material using

the horizontal plane principle.

The coefficient of friction (COF)is anumber which represents the frictionbetween two

surfaces. Friction is aresisting force relating to molecularstructure of a surface of one

materialas it slides over the surface of thesame or another material. Moleculesfrom one

surface link with molecules from the other. If you press the objects together more tightly,

you push the surfaces closer together, joining more molecules. This is why friction is

proportional to the normal force, how tightly the surfaces have to push on each other

to keep from breaking. This proportion is the coefficient of friction.

The C.O.Friction Tester can measure Static COF from a resting position and continue to move

testing surfaces in a relative motion to give an accurate kinetic COF result.

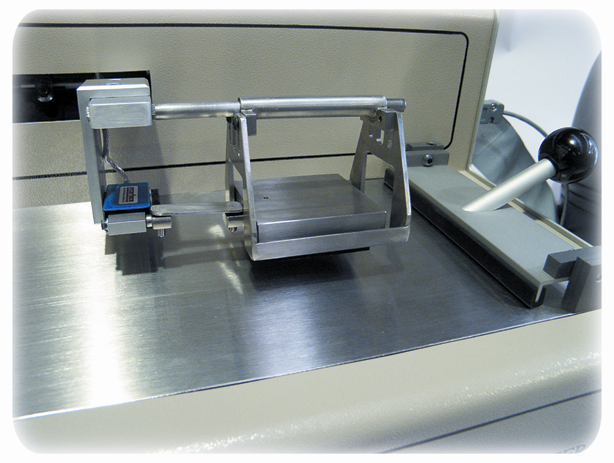

The C.O.Friction Tester employs a moving sled with a stationary table. The table has a clamping

system preventing slippage of the test piece during a test. The sled is lowered onto the table

by means of an elevator system, which places the sled so as both test surfaces meet

simultaneously,eliminating any operator error, which may influence the results of the test.

Different COF results in paper can be influenced by antiskid agents, relative humidity and

calendering.The accurate COF data obtained by using the C.O.Friction Tester aids in assessing

problem situations such as:

Roll winding problems. E.g.: crepe wrinkles, dishing, telescoping.

Web tracking problems and print misregister.

No feed or multiple feed during sheet feeding. E.g.: printing, envelopes or cartons.

Registration errors in diecutting or converting.

Corrugator runnability problems of several kinds.

Sliding on conveyor when product should not, or vice versa.

Stack or Pallet stability. e.g.: cartons, sheets, sacks, printed material.

Benefits:

Designed specifically for friction measurement.

Provides the user a means of determining the key COF parameters for their product.

Useful for quality control.

Precise and repeatable tests.

Able to test and inspect incoming materials.

Conforms to ISO 15359

Extremely easy to operate.

Operation:

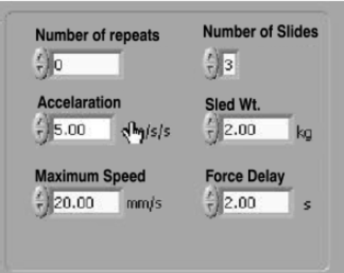

The C.O.Friction Tester Windows based software

allows the operator to set test parameters such as:

Number of Repeats

Number of Slides

Acceleration of Sled

Sled Weight

Maximum Speed

Force Delay

By default, if the operator does not choose to select or adjust any test parameters,the

system will automatically load parameters specified by ISO15359.The operator also has

the opportunity of recording Sample Identification, where data suchasOperator Name,

Description, Part Number, Standard, Date and Place can be recorded with theCOF results

for future reference. Once all relevant data has been selected and recorded, the simple

process of loading the sample ready for testing is achieved with the easy clamping system

and sled carriage. With point and click mouse control, OK will initiate the drive mechanism,

starting the test operation.

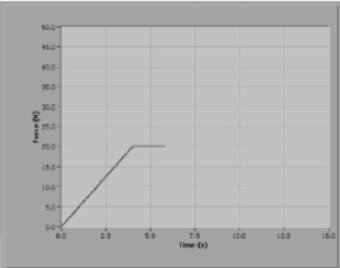

The software package is user friendly, prompting the operator through all processes, including

Accepting or Declining each individual test. This allows for any errors, such as a faulty sample,

to be deleted and not recorded as part of the final result. Rejecting a slide during a cycle of t

ests will not alter the sample number. Upon completion of a test cycle, involving the recording

COF of selected test runs, a force time graph is displayed. The X and Y axis of the graph can

be customised for the particular test being undertaken.

Besides the graph, there are two other panels containing real-time data, the output panel

and the COF panel. The test results panel shows the results accumulated during each repeat

and is updated at the end of each slide. A statistics panel shows the means of both static

and kinetic forces, both frictional and coefficient of friction.

Specifications:

Horizontal Table: 200mm x 500mm s/s flat top

surface with a fixed clamp to prevent slippage of sample

Sled: 60 x 60mm +/- 0.1mm

Sled Weight: 800g +/- 5g

Load Cell: 5lb (2.5kg)

Drive Mechanism: Close loop servo

Adjustable Pause Time after sled placement

Display of COF: Real Time Graph

Features:

Operator adjustable testing parameters

Operator promoting program for ease of use

Variable Speed Drive

Unit Selection

Data viewable after each cycle and or slide

Data storage in common file format

COF Curves are plotted in real time

Options:

Sleds:

62.5 x 62.5mm for ASTM 3247

63.5 x 63.5mm forT 816pm-92 ,T 549pm-90

and ASTM ANSI/ASTM D 1894

15 x 75mm for DIN 6729

63 x 63mm for DIN 53375 and ISO 8295

Peel Fixture:

For ASTM D3330

Sled Carriage:

Kinetic average.

Peak force value.

Printable results.

Suitable to a range of products

Easy to Operate Windows based Universal Testing Program.

Designed specifically for friction testing

Standards:

ISO 15359

ASTM 3247

ASTM ANSI / ASTM D 1894

DIN 6729

DIN 53375

ISO 8295

T 816pm-92

T 549pm-90

Connections:

Electrical: 220/240 VAC @ 50 HZ or

Electrical: 110 VAC @ 60 HZ

(please specify when ordering)

Dimensions:

H: 300mm

W: 650mm

D: 450mm

Weight: 15kg

Product detail pictures:

Related Product Guide:

Discount EKG Machines Make Home Testing Easier

What Are Impact Test Machines?

We can constantly satisfy our respected customers with our good high quality, good price tag and good support due to we have been additional specialist and extra hard-working and do it in cost-effective way for OEM/ODM China Wt2080 Led Power Driver Tester - C0041 – COFriction Tester – Drick, The product will supply to all over the world, such as: Botswana, Zambia, Irish, Establish long term and win-win business relationships with all our customers, share the success and enjoy the happiness of spreading our products to the world together. Trust us and you will gain more. Please feel free to contact us for more information, we assure you of our best attention at all times.

SHANDONG DRICK INSTRUMENTS CO.,LTD

Company Profile

Shandong Drick Instruments Co., Ltd, is mainly engaged in the research and development, manufacturing and sales of testing instruments.

The company established in 2004.

Products are used in scientific research units, quality inspection institutions, universities, packaging, paper, printing, rubber and plastics, chemicals, food, pharmaceuticals, textiles, and other industries.

Drick pays attention to talent cultivation and team building, adhering to the development concept of professionalism, dedication.pragmatism, and innovation.

Adhering to the customer-oriented principle, solve the most urgent and practical needs of customers, and provide first-class solutions to customers with high-quality products and advanced technology.

Production management mechanism is completed, quality is guaranteed, high credibility and service let the cooperation is easy, perfect!