DRK646 Xenon lamp aging test chamber

Short Description:

1、Product manual The destruction of materials by sunlight and moisture in nature causes incalculable economic losses every year. The damage caused mainly includes fading, yellowing, discoloration, strength reduction, embrittlement, oxidation, brightness reduction, cracking, blurring and chalking. Products and materials that are exposed to direct or behind-the-glass sunlight are at greatest risk of photodamage. Materials exposed to fluorescent, halogen, or other light-emitting lamps for exten...

DRK646 Xenon lamp aging test chamber Detail:

1、Product manual

The destruction of materials by sunlight and moisture in nature causes incalculable economic losses every year. The damage caused mainly includes fading, yellowing, discoloration, strength reduction, embrittlement, oxidation, brightness reduction, cracking, blurring and chalking. Products and materials that are exposed to direct or behind-the-glass sunlight are at greatest risk of photodamage. Materials exposed to fluorescent, halogen, or other light-emitting lamps for extended periods of time are also affected by photodegradation.

The Xenon Lamp Weather Resistance Test Chamber uses a xenon arc lamp that can simulate the full sunlight spectrum to reproduce the destructive light waves that exist in different environments. This equipment can provide corresponding environmental simulation and accelerated tests for scientific research, product development and quality control.

The DRK646 xenon lamp weather resistance test chamber can be used for tests such as selection of new materials, improvement of existing materials or evaluation of changes in durability after changes in material composition. The device can well simulate the changes in materials exposed to sunlight under different environmental conditions.

Simulates the full sunlight spectrum:

The Xenon Lamp Weathering Chamber measures the light resistance of materials by exposing them to ultraviolet (UV), visible, and infrared light. It uses a filtered xenon arc lamp to produce the full sunlight spectrum with maximum matching to sunlight. A properly filtered xenon arc lamp is the best way to test a product’s sensitivity to longer wavelength UV and visible light in direct sunlight or sunlight through glass.

Lightfastness testing of interior materials:

Products placed in retail locations, warehouses, or other environments can also experience significant photodegradation due to prolonged exposure to fluorescent, halogen, or other light-emitting lamps. The xenon arc weather test chamber can simulate and reproduce the destructive light produced in such commercial lighting environments, and can accelerate the test process at higher intensity.

simulated climate environment:

In addition to the photodegradation test, the xenon lamp weather test chamber can also become a weathering test chamber by adding a water spray option to simulate the damage effect of outdoor moisture on materials. Using the water spray function greatly expands the climatic environmental conditions that the device can simulate.

Relative Humidity Control:

The xenon arc test chamber provides relative humidity control, which is important for many humidity-sensitive materials and is required by many test protocols.

The main function:

▶A variety of filter systems to choose from;

▶Solar eye irradiance control;

▶ Relative humidity control;

▶Blackboard/or test chamber air temperature control system;

▶Test methods that meet the requirements;

▶Irregular shape holder;

▶Replaceable xenon lamps at reasonable prices.

Light source that simulates the full sunlight spectrum:

The device uses a full-spectrum xenon arc lamp to simulate the damaging light waves in sunlight, including UV, visible and infrared light. Depending on the desired effect, the light from a xenon lamp is usually filtered to produce a suitable spectrum, such as the spectrum of direct sunlight, sunlight through glass windows, or the UV spectrum. Each filter produces a different distribution of light energy.

The life of the lamp depends on the irradiance level used, and the life of the lamp is generally about 1500~2000 hours. Lamp replacement is easy and quick. Long-lasting filters ensure that the desired spectrum is maintained.

When you expose the product to direct sunlight outdoors, the time of day that the product experiences maximum light intensity is just a few hours. Even so, the worst exposures only occur during the hottest weeks of the summer. Xenon lamp weather resistance test equipment can speed up your test process, because through program control, the equipment can expose your product to a light environment equivalent to the noon sun in summer 24 hours a day. The exposure experienced was significantly higher than the outdoor exposure in terms of both average light intensity and light hours/day. Thus, it is possible to accelerate the acquisition of test results.

Control of light intensity:

Light irradiance refers to the ratio of light energy impinging on a plane. The equipment must be able to control the irradiance intensity of the light in order to achieve the purpose of accelerating the test and reproducing the test results. Changes in light irradiance affect the rate at which material quality deteriorates, while changes in the wavelength of light waves (such as the energy distribution of the spectrum) simultaneously affect the rate and type of material degradation.

The irradiation of the device is equipped with a light-sensing probe, also known as the sun eye, a high-precision light control system, which can compensate in time for the decline in light energy due to lamp aging or any other changes. The solar eye allows the selection of an appropriate light irradiance during testing, even a light irradiance equivalent to the midday sun in summer. The solar eye can continuously monitor the light irradiance in the irradiation chamber, and can precisely keep the irradiance at the working set value by adjusting the power of the lamp. Due to long-term work, when the irradiance drops below the set value, a new lamp needs to be replaced to ensure the normal irradiance.

Effects of Rain Erosion and Moisture:

Due to frequent erosion from rain, the coating layer of wood, including paints and stains, will experience corresponding erosion. This rain-washing action washes away the anti-degradation coating layer on the surface of the material, thereby exposing the material itself directly to the damaging effects of UV and moisture. The rain shower feature of this unit can reproduce this environmental condition to enhance the relevance of certain paint weathering tests. The spray cycle is fully programmable and can be run with or without a light cycle. In addition to simulating moisture-induced material degradation, it can effectively simulate temperature shocks and rain erosion processes.

The water quality of the water spray circulation system adopts deionized water (solid content is less than 20ppm), with the water level display of the water storage tank, and two nozzles are installed on the top of the studio. Adjustable.

Moisture is also the main factor causing the damage of some materials. The higher the moisture content, the more accelerated the damage to the material. Humidity can affect the degradation of indoor and outdoor products, such as various textiles. This is because the physical stress on the material itself increases as it tries to maintain a moisture balance with the surrounding environment. Therefore, as the humidity range in the atmosphere increases, the overall stress experienced by the material is greater. The negative effect of humidity on the weatherability and colorfastness of materials is widely recognized. The moisture function of this device can simulate the effect of indoor and outdoor moisture on materials.

The heating system of this equipment adopts far-infrared nickel-chromium alloy high-speed heating electric heater; high temperature, humidity, and illumination are completely independent systems (without interfering with each other); temperature control output power is calculated by microcomputer to achieve high-precision and high-efficiency electricity consumption benefit.

The humidification system of this equipment adopts an external boiler steam humidifier with automatic water level compensation, water shortage alarm system, far-infrared stainless steel high-speed heating electric heating tube, and humidity control adopts P.I.D + S.S.R, the system is on the same channel Coordinated control.

2、Introduction to Structural Design

1. Since the design of this equipment emphasizes its practicability and ease of control, the equipment has the characteristics of easy installation, simple operation, and basically no daily maintenance;

2. The equipment is mainly divided into main part, heating, humidification, refrigeration and dehumidification part, display control part, air conditioning part, safety protection measures part and other accessory parts;

3. The equipment is fully automated and can work continuously 24 hours a day, 7 days a week;

4. The unique sample rack tray of this equipment is very convenient to use. The tray is inclined 10 degrees from the horizontal direction, and can place flat specimens of different shapes and sizes or three-dimensional samples, such as parts, components, bottles and test tubes. This tray can also be used to test materials that flow in high temperature environments, materials exposed to bacterial petri dishes, and materials that act as waterproofing on roofs;

5. The shell is processed and formed by high-quality A3 steel plate CNC machine tool, and the surface of the shell is sprayed to make it more smooth and beautiful (now upgraded to arc corners); the inner tank is imported SUS304 high-quality stainless steel plate;

6. The reflective light of the mirror stainless steel plate is designed, which can reflect the upper light to the lower sample area;

7. The stirring system adopts a long-axis fan motor and a stainless steel multi-wing impeller that is resistant to high and low temperatures to achieve strong convection and vertical diffusion circulation;

8. Double-layer high-temperature-resistant high-tension sealing strips are used between the door and the box to ensure the airtightness of the test area; the non-reaction door handle is used for easier operation;

9. High-quality fixable PU movable wheels are installed at the bottom of the machine, which can easily move the machine to the designated position, and finally fix the casters;

10. The equipment is equipped with a visual observation window. The observation window is made of tempered glass and pasted with black automotive glass film to protect the eyes of the staff and to observe the test process clearly.

3、Detailed specifications

▶Model: DRK646

▶Studio size: D350*W500*H350mm

▶Sample tray size: 450*300mm (effective irradiation area)

▶Temperature range: normal temperature~80℃ adjustable

▶Humidity range: 50~95% R•H adjustable

▶Blackboard temperature: 40~80℃ ±3℃

▶Temperature fluctuation: ±0.5℃

▶Temperature uniformity: ±2.0℃

▶Filter: 1 piece (glass window filter or quartz glass filter according to customer needs)

▶Xenon lamp source: air-cooled lamp

▶Number of xenon lamps: 1

▶Xenon lamp power: 1.8 KW/each

▶Heating power: 1.0KW

▶ Humidification power: 1.0KW

▶ Distance between sample holder and lamp: 230~280mm (adjustable)

▶Xenon lamp wavelength: 290~800nm

▶The light cycle is continuously adjustable, time: 1~999h, m, s

▶Equipped with radiometer: 1 UV340 radiometer, the narrow-band irradiance is 0.51W/㎡;

▶Irradiance: The average irradiance between the wavelengths of 290nm and 800nm is 550W/㎡;

▶The irradiance can be set and automatically adjusted;

▶Automatic spray device;

4、Circuit control system

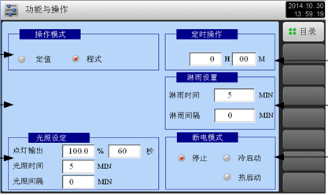

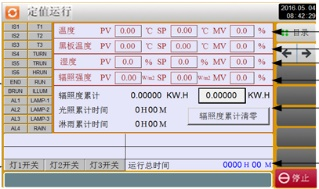

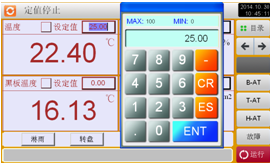

▶The control instrument adopts imported 7-inch color touch screen program control instrument, with large screen, simple operation, easy program editing, with R232 communication port, setting and displaying box temperature, box humidity, blackboard temperature and irradiance;

▶The control instrument adopts imported 7-inch color touch screen program control instrument, with large screen, simple operation, easy program editing, with R232 communication port, setting and displaying box temperature, box humidity, blackboard temperature and irradiance;

▶Accuracy: 0.1℃ (display range);

▶Accuracy: 0.1℃ (display range);

▶ Resolution: ±0.1℃;

▶Temperature sensor: PT100 platinum resistance temperature measuring body;

▶Control method: heat balance temperature and humidity adjustment method;

▶Temperature and humidity control adopts P.I.D+S.S.R system co-channel coordinated control;

▶It has the function of automatic calculation, which can immediately correct the changing conditions of temperature and humidity, so that the temperature and humidity control is more accurate and stable;

▶The operation interface of the controller is available in Chinese and English, and the real-time operation curve can be displayed on the screen;

▶It has 100 groups of programs, each group has 100 segments, and each segment can cycle 999 steps, and the maximum time for each segment is 99 hours and 59 minutes;

▶After the data and test conditions are input, the controller has a screen lock function to avoid shutdown by human touch;

▶With RS-232 or RS-485 communication interface, you can design programs on the computer, monitor the test process and perform functions such as automatic switch on and off, print curves, and data;

▶The controller has an automatic screen saver function, which can better protect the LCD screen under long-term operation (making the life longer);

▶Precise and stable control, long-term operation without drift;

▶1s ~999h, m, S can arbitrarily set the spray stop time;

▶The meter displays four screens: cabinet temperature, cabinet humidity, light intensity, and blackboard temperature;

▶Equipped with UVA340 or full spectrum mounted irradiator to detect and control irradiance in real time;

▶The independent control time of illumination, condensation and spraying and the program and time of alternate cycle control can be set arbitrarily;

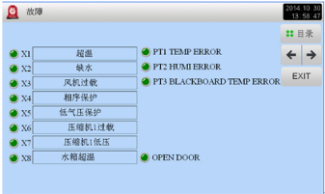

▶In the operation or setting, if there is an error, a warning number will be provided; electrical components such as “ABB”, “Schneider”, “Omron”;

5、Refrigeration and dehumidification system control

5、Refrigeration and dehumidification system control

▶Compressor: fully enclosed French Taikang;

▶ Refrigeration method: mechanical stand-alone refrigeration;

▶Condensation method: air-cooled;

▶Refrigerant: R404A (environmentally friendly);French “Taikang” compressor

▶The whole system pipelines are tested for leakage and pressurization for 48H;

▶The heating and cooling systems are completely independent;

▶Inner spiral refrigerant copper tube;

▶ Fin slope type evaporator (with automatic defrosting system);

▶The filter drier, refrigerant flow window, repair valve, oil separator, solenoid valve and liquid storage tank are all imported original parts;

Dehumidification system: The evaporator coil dew point temperature laminar flow contact dehumidification method is adopted.

6、Protection System

▶Fan overheating protection;

▶Overall equipment phase loss/reverse phase protection;

▶Overload protection of refrigeration system;

▶Overpressure protection of refrigeration system;

▶Over temperature protection;

▶Others include leakage, water shortage indication, automatic shutdown after fault alarm.

7、Conditions of use of the equipment

▶Ambient temperature: 5℃~+28℃ (average temperature within 24 hours≤28℃);

▶Ambient humidity: ≤85%;

▶Power requirements: AC380 (±10%) V/50HZ three-phase five-wire system;

▶Preinstalled capacity: 5.0KW.

8、Spare parts and technical data

▶Provide spare parts (wearing parts) necessary to ensure the safe, stable and reliable operation of the equipment during the warranty period;

▶Provide operation manual, instrument manual, packing list, spare parts list, electrical schematic diagram;

▶And other relevant information required by the seller for the correct use and maintenance of the equipment by the buyer.

9、Applicable Standards

▶GB13735-92 (Polyethylene blow molding agricultural ground cover film)

▶GB4455-2006 (Polyethylene blown shed film for agriculture)

▶GB/T8427-2008 (Textile color fastness test artificial color resistance xenon arc)

▶At the same time comply with GB/T16422.2-99

▶GB/T 2423.24-1995

▶ASTMG155

▶ISO10SB02/B04

▶SAEJ2527

▶SAEJ2421 and other standards.

10、Main configuration

▶ 2 air-cooled xenon lamps (one spare):

Domestic 2.5KW Xenon Lamp Domestic 1.8KW Xenon Lamp

Domestic 2.5KW Xenon Lamp Domestic 1.8KW Xenon Lamp

▶Xenon lamp power supply and trigger device: 1 set (customized);

▶One set of radiometer: UV340 radiometer;

▶French Taikang dehumidification and refrigeration unit 1 group;

▶The inner tank of the box is made of SUS304 stainless steel plate, and the outer shell is made of A3 steel plate with plastic spray treatment;

▶Special sample holder;

▶Color touch screen, directly display the box temperature and humidity, irradiance, blackboard temperature, and automatically adjust;

▶High quality positioning adjustable height casters;

▶Schneider electrical components;

▶A water tank with enough water for testing;

▶High temperature and high pressure magnetic water pu

Product detail pictures:

Related Product Guide:

Points To Consider While Choosing Lab Testing Machines for Your Industrial Laboratory

Wide Usage of Gold Testing Machine

The organization keeps on the procedure concept "scientific management, high quality and efficiency primacy, purchaser supreme for DRK646 Xenon lamp aging test chamber, The product will supply to all over the world, such as: Oman, Libya, Bhutan, They are sturdy modeling and promoting effectively all over the world. Never ever disappearing major functions within a quick time, it's a have to for you of fantastic good quality. Guided by the principle of Prudence, Efficiency, Union and Innovation. the corporation. ake an excellent efforts to expand its international trade, raise its organization. rofit and raise its export scale. We are confident that we are going to have a bright prospect and to be distributed all over the world in the years to come.

SHANDONG DRICK INSTRUMENTS CO.,LTD

Company Profile

Shandong Drick Instruments Co., Ltd, is mainly engaged in the research and development, manufacturing and sales of testing instruments.

The company established in 2004.

Products are used in scientific research units, quality inspection institutions, universities, packaging, paper, printing, rubber and plastics, chemicals, food, pharmaceuticals, textiles, and other industries.

Drick pays attention to talent cultivation and team building, adhering to the development concept of professionalism, dedication.pragmatism, and innovation.

Adhering to the customer-oriented principle, solve the most urgent and practical needs of customers, and provide first-class solutions to customers with high-quality products and advanced technology.

The sales manager is very patient, we communicated about three days before we decided to cooperate, finally, we are very satisfied with this cooperation!