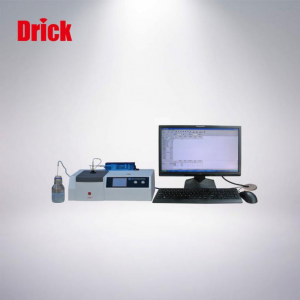

Pressure blasting test machine for pipe material DRK655

Short Description:

The products are in accordance with ISO 1167, GB/T 6111, GB/T15560, ASTM D1598, ISO9080, GB 18252, CJ/T108-1999 and ASTM F1335 for the long term pressure test method and the standard of the instantaneous blasting test method for plastic pipes and composite pipes. Configuration description Pressure blasting test machine for XGNB-N-B- 6 pipe MasterOverall dimension: 560*590*1250mm Panel computer (XP software, touch screen), color printer (二) Mechanical attachment Ov...

The products are in accordance with ISO 1167, GB/T 6111, GB/T15560, ASTM D1598, ISO9080, GB 18252, CJ/T108-1999 and ASTM F1335 for the long term pressure test method and the standard of the instantaneous blasting test method for plastic pipes and composite pipes.

Configuration description

- Pressure blasting test machine for XGNB-N-B- 6 pipe

- MasterOverall dimension: 560*590*1250mm

Panel computer (XP software, touch screen), color printer

(二) Mechanical attachment

Overall dimension: 600*540*1000mm

Motor, waterway part (Pipe and solenoid valve)

1. The master ofpressure test machine

(1) 1 platform for industrial control panel computer

(2) 1 set of control systems, including 6 sets of precision pressure control units.

(3) 1 set of integrated printing equipment

2. Mechanical attachment

(1) 1 sets of imported water pressure stations (United States);

(2) Main pressure (decompression) module 1, including imported Holland solenoid valve 1, high precision sensor (Switzerland) 1, main accumulator 1.

(3) Branch module 6, including imported solenoid valves (Holland), each road has 2 branches, a total of 12, the high-precision sensor has 1 branches per 6, and the branch accumulator has 6 branches per Road 1.

(4) 1 filters

3. Pressure test software

4. Relevant tools and attachment

5. Power line, communication data line

6. Supporting user manuals (instructions), certificate of conformity, packing list, etc.

Performance introduction

1. Industrial control tablet computers replace the traditional way, full touch operation.

2. Excellent performance, easy manipulation, handwriting, keyboard input, pre installed software, reducing the space occupied by desktop computers.

3. Integrated printing equipment to reduce the customer’s separate printer case.

4. Separation of water and electricity, divided into electrical control box and mechanical water box, improve safety performance.

5.The mechanical part is modular design, each branch is a module, the module share the main pressure and pressure relief, the module’s branch pressure is independent, the single way adjustment and cut-off, the pressure reverse cut-off, do not affect each other. Module docking connection, if you need to add a few roads, add several modules, do not need to increase the pipeline (except the output line), minimize the pipeline, thus reducing the noise produced by the operation of the equipment.

6. For later expansion, only the electrical mainframe will increase the control board, and the mechanical part can be added to the module (up to 90 roads).

7. The solenoid valve is a plate type solenoid valve

8. The filter is a front-end filter, with a built-in micron grade stainless steel filter element.

Main technical parameters

- pressure range 0 – 10MPa

- resolution 0.001 MPa

- Controlled pressure precision is better than + 1% (adjustable pressure tolerance band – MAX + 0.0001 MPa).

- Various control parameters (pressure, time and accuracy) can be input or adjusted.

- real-time display time (the maximum of 9999 hours and 59 minutes and 59 seconds) pressure (three points after the decimal point) and eight test states (lift, fill, pressure, operation, end, leak, burst) at the same time when the pressure, end, leakage, burst four state when there is sound and light alarm.

- It can observe, analyze, query, store, print, test curve (pressure time) and start time, set time, current time; effective time, invalid time; remaining time, overvoltage time, filling time and other time parameters

The thermostatic water container

450 horizontal constant temperature water tanks

Internal size: 1800*640*900mm,

Outer size: 2500*1010*1055mm

Temperature control system: a set of 15-95 degrees centigrade

Include: temperature control box

1 cryogenic refrigerator

Main technical parameters:

This series of constant temperature medium box (water tank) is a necessary equipment for the long hydrostatic test, pressure resistance and instantaneous blasting test of various plastic pipes such as PVC, PE, PP-R and ABS, which are necessary for the Research Institute, the quality inspection department and the pipe production enterprise.

Comply with GB/T 6111-2003, GB/T 15560-95, GB/T 18997.1-2003, GB/T 18997.2-2003, ISO 1167-2006, ASTM D1598-2004, ASTM D1599 and other standard requirements.

Product features

The structure design of the box structure is reasonable, and multiple samples are tested at the same time. Independent operation is independent of each other. The temperature control is stable and the precision is high. All the water contactor is made of stainless steel (pipe, pipe, heater, valve and so on). Using the bottom of the frame, it can carry the weight of the medium and the tube sample in the box, and the inside of the box is equipped with a specimen hanging bar to conveniently place the sample.

Temperature control system:

It is controlled by the intelligent interface. The temperature and control tolerance (upper and lower limits) can be set arbitrarily. At the same time, it can record the temperature data of the water tank for hundreds of hours, and can be transferred from the serial port or the USB port to the computer for the curve display at the same time.

Circulatory system:

The imported brand efficient circulation pump has strong circulation capability and good temperature uniformity.

Resistance to corrosion:

The inner liner is made of high quality stainless steel and has no rust for a long time. The exterior is painted with rust proof steel plate.

Excellent thermal insulation performance:

With high quality insulation material (80MM ~ 100MM of insulation layer thickness), full isolation between inner and outer layers of the box can effectively avoid heat conduction, and reduce the heat bridge (short circuit) measures and save electricity.

Water level measurement / intelligent water replenishment:

It can be equipped with water level measuring system and intelligent water replenishing system. The water supplement system is controlled by the temperature signal when water level measurement system needs to make water. Only when the water is kept under the constant temperature, the water supply is adjustable, and the process of water replenishment does not affect the temperature stability of the water tank.

Automatic opening:

The large water tank lid is opened by pneumatic, the small water tank helps to open, the angle can be controlled arbitrarily, and the use is safe and convenient, and saves time and effort.

Compatibility performance:

Not only can it be used in conjunction with the XGNB series of different specifications of the test engine, but it can also be used in conjunction with the international common brand test host.

Technical parameter

1. The range of temperature control: 15 ~ 95 C

2. Temperature display precision: 0.01 C

3. Temperature control precision: + 0.5 C

4. Temperature uniformity: + 0.5 C

5. Control mode: intelligent instrument control, which can record temperature data for hundreds of hours.

6. Display mode: display in liquid crystal (English)

7. Open mode: pneumatic opening

8. Data interface: the communication line can be connected to the computer, and the PC can monitor and record the temperature data and curve changes in real time.

9. Other functions: automatic water replenishing device, intelligent water replenishing process will not affect the test process and result.

10. Liner material: water tank and piping, pipe fittings and other parts contacted with water are all made of high quality stainless steel.

Pressure resistance clamp

Technical parameters / specifications

|

Specifications |

Max Outside Diameter |

Type circle |

Nominal pressure |

Material |

|

|

Stainless steel |

carbon steel |

||||

|

DN10mm |

Φ48mm |

Φ3.55×10 |

16Mpa |

√ |

× |

|

DN16mm |

Φ54mm |

Φ3.5×16 |

16Mpa |

√ |

× |

|

DN18mm |

Φ54mm |

Φ3.55×18 |

16Mpa |

√ |

× |

|

DN20mm |

Φ50mm |

Φ3.55×20 |

16Mpa |

√ |

× |

|

DN25mm |

Φ63mm |

Φ3.55×25 |

16Mpa |

√ |

× |

|

DN32mm |

Φ61mm |

Φ3.55×32 |

16Mpa |

√ |

× |

|

DN40mm |

Φ69mm |

Φ3.55×40 |

16Mpa |

√ |

× |

|

DN50mm |

Φ80mm |

Φ3.55×50 |

10Mpa |

√ |

× |

|

DN63mm |

Φ103mm |

Φ3.55X63 |

10Mpa |

√ |

× |

|

DN75mm |

Φ122mm |

Φ5.3×75 |

10Mpa |

√ |

× |

|

DN90mm |

Φ137mm |

Φ5.3×90 |

10Mpa |

√ |

× |

|

DN110mm |

Φ170mm |

Φ5.3×110 |

10Mpa |

√ |

× |

|

DN125mm |

Φ185mm |

Φ5.7×120 |

10Mpa |

√ |

√ |

|

DN140mm |

Φ205mm |

Φ5.7×135 |

10Mpa |

√ |

√ |

|

DN160mm |

Φ232mm |

Φ7×160 |

10Mpa |

√ |

√ |

|

DN180mm |

Φ255mm |

Φ7×180 |

10Mpa |

√ |

√ |

|

DN200mm |

Φ277mm |

Φ7×200 |

10Mpa |

√ |

√ |

|

DN225mm |

Φ302mm |

Φ7×225 |

10Mpa |

√ |

√ |

|

DN250mm |

Φ335mm |

Φ8.6×245 |

10Mpa |

√ |

√ |

|

DN280mm |

Φ382mm |

Φ12×275 |

6Mpa |

√ |

√ |

|

DN315mm |

Φ425mm |

Φ12×310 |

6Mpa |

√ |

√ |

|

DN355mm |

Φ465mm |

Φ12×345 |

6Mpa |

√ |

√ |

|

DN400mm |

Φ516mm |

Φ16×392 |

6Mpa |

√ |

√ |

|

DN450mm |

Φ566mm |

Φ16×440 |

6Mpa |

√ |

√ |

|

DN500mm |

Φ642mm |

Φ16×490 |

6Mpa |

√ |

√ |

|

DN560mm |

Φ702mm |

Φ18×550 |

6MPa |

√ |

√ |

|

DN630mm |

Φ772mm |

Φ18×620 |

6MPa |

√ |

√ |

|

DN710mm |

Φ857mm |

Φ20×700 |

3MPa |

√ |

√ |

|

DN800mm |

Φ948mm |

Φ20×790 |

3MPa |

√ |

√ |

|

DN900mm |

Φ1078 |

Φ32×890 |

3MPa |

√ |

√ |

|

DN1000mm |

Φ1178 |

Φ32×990 |

2.5Mpa |

√ |

√ |

|

DN1200mm |

Φ1378 |

Φ32×1190 |

2.5Mpa |

√ |

√ |

SHANDONG DRICK INSTRUMENTS CO.,LTD

Company Profile

Shandong Drick Instruments Co., Ltd, is mainly engaged in the research and development, manufacturing and sales of testing instruments.

The company established in 2004.

Products are used in scientific research units, quality inspection institutions, universities, packaging, paper, printing, rubber and plastics, chemicals, food, pharmaceuticals, textiles, and other industries.

Drick pays attention to talent cultivation and team building, adhering to the development concept of professionalism, dedication.pragmatism, and innovation.

Adhering to the customer-oriented principle, solve the most urgent and practical needs of customers, and provide first-class solutions to customers with high-quality products and advanced technology.